Page 6 of 6

Posted: Mon Jul 02, 2007 6:01 pm

by tx river rat

Mick

Thats the way I did mine but I am always looking for a faster easier way.

Ron

In the Sea of TEXAS

Posted: Fri Jul 13, 2007 6:27 pm

by gken

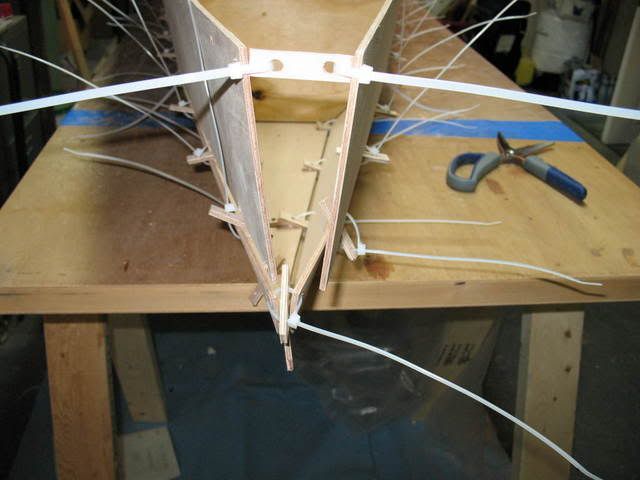

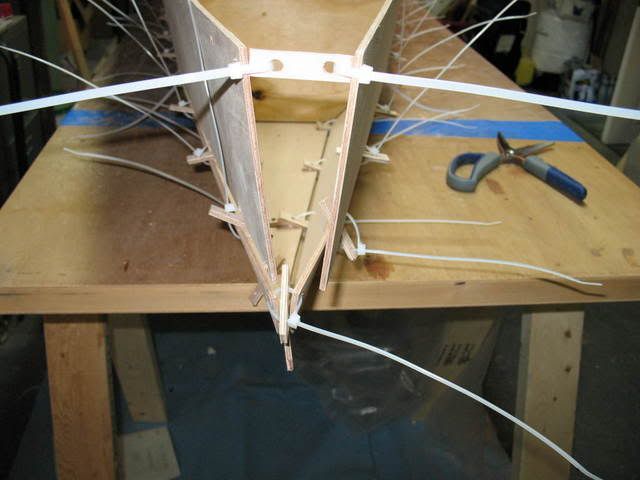

Alright all you experts, or at least builders with more know how than me. What do I do to fix this little problem? I know in the instructions I am told to trim the ends if needed, well I think I need to. How do I go about doing this?

That is a 2" long spacer in between the two panels. That is how far apart the panels have to be in order to make the seams line up properly.

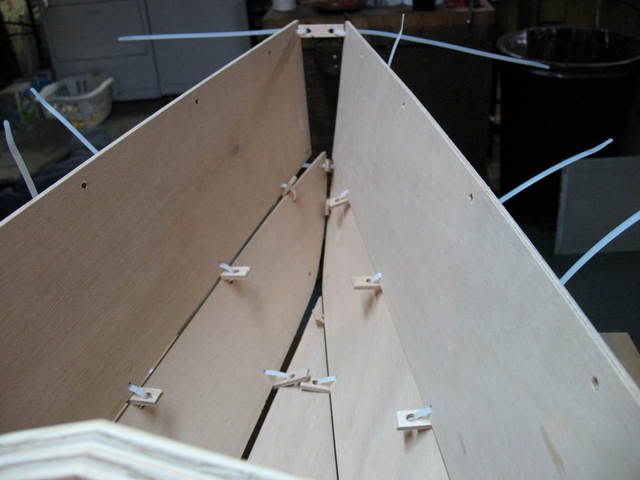

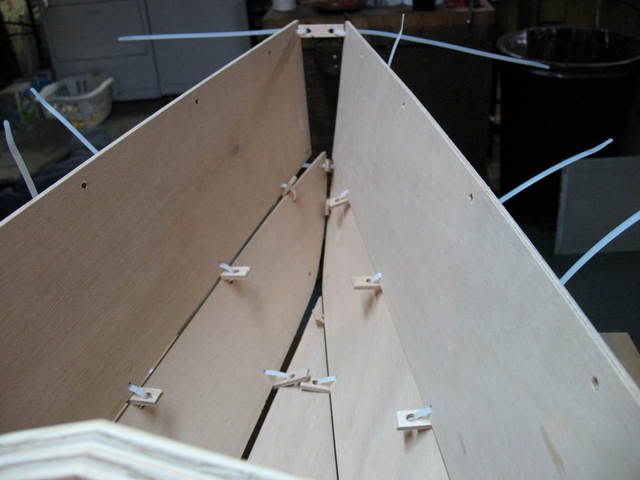

That is the inside view for all of you who didnt know.

and this is how helpful my co-builder is when the going gets tough...

So, as you can see I really need you guys on this one as I dont believe that my son has any ideas. Thanks in advance --Garrett

Posted: Fri Jul 13, 2007 6:36 pm

by jem

First: you spacers are too thick. You'll end up using a lot of filleting material.

I'm not sure why you're not pulling the end together. How does that make the seam not line up? Did you measure diagonals per the QA1 drawing before you cut?

Can you provide a side view?

Posted: Fri Jul 13, 2007 6:54 pm

by hairymick

G'day Garret,

Are your side panels identical in length?

Are the panels immediately below lined up?

Do your butt Joints line up with each other?

Can you cynch the ends of the opanels intogether and then take a series of side on piccies please.

If your opposite panels are the same, it should work out.

Something is probably out of alignment somewhere. I am tipping it will probably be your butt joints aren't lining up. One or more panels might be a little too far forward or back. I would check them first.

If that checks out OK, You might need to take those panels off and re-do the quality assurance checks on the panels as set out in the plans.

Before you do that, however, check the diagonal measurements between the temp hull stations as is also detailed in the plans. If the stations are stitched into the correct placings, the diagonal measurements should be identical. If not, your boat is not square.

If the panels were all cut correctly and the Q.A. checks out, the problem won't be major. something will simply be out of alignment.

I would start from where you are at now and work backwards, checking your measurements as you go till you find the problem.

start by checking the butt joint seams line up.

Then check hull station diagonals

Then, if the problem is still not apparent, remove a side panel ( the last one you put on) and check its QA measurements. Keep going backwards till you find the problem.

Posted: Fri Jul 13, 2007 9:07 pm

by gken

I will take the requested piccies tomorrow when I get home from work , as I am off to bed here in a moment. I just wanted to give you a bit more info. I left out a lot of what I meant to tell you. The bow (its the stern I am having trouble with) lines up beautifully. I had it the stern stitched together earlier and I couldnt get the seams to line up. The top panels wanted to sit inside of the bottom panels. I measured the top and bottom panels. The top panels are spot on, and one of the bottom panels is about a 16th of an inch long. The other is exact.

The pictures will tell the story better than I can, so if there are any views other than side, and with the end stitched together that you would like to see, post your request here and I will check in tomorrow afternoon before I go back to work on her.

Matt, I thought the manual suggests using spacers the same thickness as the building material. Is this wrong? I would prefer not to have to take her apart again, but I will of you say I need to.

Thanks for your quick responses everyone. I will get back to you soon. --Garrett

Posted: Fri Jul 13, 2007 9:26 pm

by tx river rat

Do your spacers have two holes in them if so they will not tighten up ties just need to be thru one hole.

Ron

Posted: Fri Jul 13, 2007 9:28 pm

by jem

spacers: They should say to make from craft sticks (tongue depressors).

Posted: Fri Jul 13, 2007 9:43 pm

by hairymick

heya Garret,

i think I might understand your problem now.

Is it that your second side panels won't quite line up with the lower side panels?

If this is the case - no problem

On all my boats, at the stems the ply needed a little torturing and twisting to get the panels to line up.

Sometimes ya gotta do what ya gotta do.

Check out my builds on Southwind, swampgirl or wadefish and you will see what I mean. if you can't find them, i will post piccies for you.

Posted: Fri Jul 13, 2007 11:23 pm

by jem

ok if what Mick is saying is correct, you do have to give those bottom panels a little bit of a twist.

It's a small twist so the ply should take it fine.

Posted: Sat Jul 14, 2007 3:39 am

by hairymick

Here is what I did, to get the panels to line up on my Southwind.

My IT skills are very poor and I can't draw you a diagram. sorry.

I took some off-cuts about 1/4 X 3/4 and wrapped some tie wire around one of them, leaving about a foot or so of wire on each end. Holding the off-cut against the side of the boat, feed the wires through the gap between the panels and out the corresponding gap on the other side of the boat. Pull the wires so that they are firm and holding your first off- cut against the panels, Now take a second similar off-cut and twist the wire around it to hold it against the opposite side of the boat.

When done, It should look something like this.

You will probably need two or three clamping sticks like this.

Once you have them in place, GENTLY twist the wire on one side to gradually tighten it and pull the sides in togather. Twist a little on each clamping stick, working them all to gradually pull the sides in. don't try to over tighten one and just leave the other. There should be similar tension on all your wires and sticks - all of the time.

In the piccies you will also see come pieces of ply screwed into the hull here and there. There are also some wedges. These are just for fine tuning and are probably not necessary on a freedom.

Hope this helps a bit mate.